Background

10.1

This section of the EIA presents a summary of the analysis and findings

of the Quantitative Risk Assessment (QRA) study undertaken for the proposed

West Island Line (WIL) project. This project consists of approximately 3.3 km extension to the Island Line (ISL)

from the existing Sheung Wan Station (SHW) to the new Kennedy Town Station

(KET). The extension incorporates two new intermediate stations at Sai Yin Pun

(SYP) and Hong Kong University (UNV). Construction is scheduled to commence in early

2009 for completion in 2014.

10.2

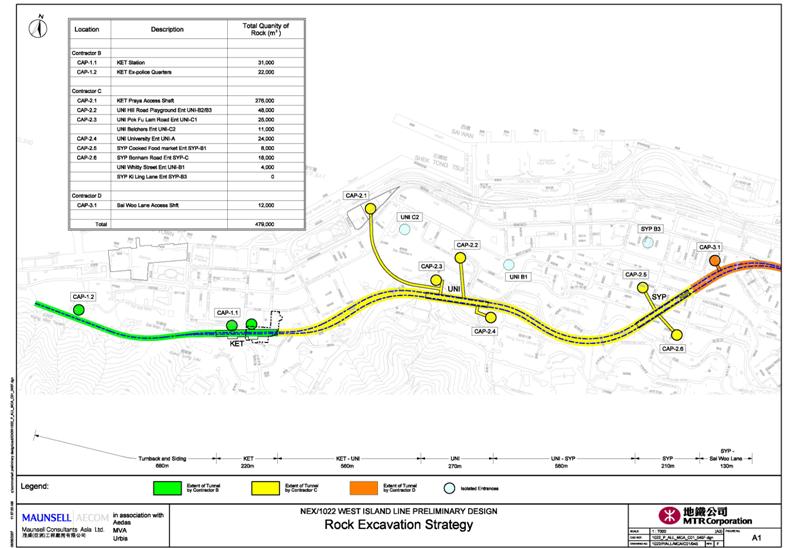

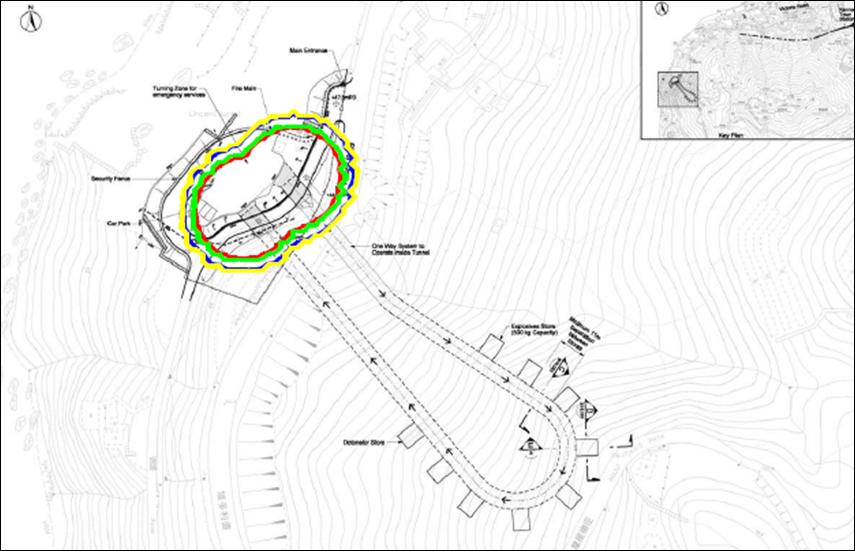

A significant length of the WIL tunnels, adits and station boxes will be

excavated in rock. The rock spoil is to be removed from a number of access

shafts and tunnels as shown in Figure 3. A significant amount of explosives

will be required for the construction of rock caverns, tunnels and adits for

the WIL. Therefore, the project allows for the construction and operation of an

underground explosives storage magazine located beneath Mount Davies.

10.3

Further details of the analysis pertaining to the storage, transport and

use of explosives for the WIL project are presented in the Appendix 10.

Legislation requirement and evaluation criteria

10.4

The

key legislation and guidelines that are

considered relevant to the development of the proposed West Island Line project

are as follows:-

·

Dangerous

Goods Ordinance, Chapter 295;

·

Environmental

Impact Assessment Ordinance (EIAO), Chapter 499; and

·

The

EIA Study Brief, Section 3.4.6

EIAO

Technical Memorandum (EIAO-TM)

10.5

The

requirement for a QRA of projects that involve the storage, use and transport

of dangerous goods where a risk to life is a key issue with respect to the Hong Kong Government

Risk Guidelines (HKRG) is specified in Section 12 of the Environmental Impact

Assessment Ordinance Technical Memorandum (EIAO-TM).

10.6

The relevant authority for a QRA study relating to an explosives

magazine storage facility, the transport and subsequent use of the explosives

is the Environmental Protection Department (EPD), as specified in Annex 22 of

the EIAO-TM.

10.7

Annex 4 of the EIAO-TM specifies the Individual and Societal Risk

Guidelines.

Hong Kong Government Risk Guidelines

(HKRG), EIAO TM Annex 4

10.8

Individual risk is the predicted increase in the chance of fatality per

year to an individual due to a potential hazard. The individual risk guidelines

require that the maximum level of individual risk should not exceed 1 in 100,000 per year i.e. 1 x10-5

per year.

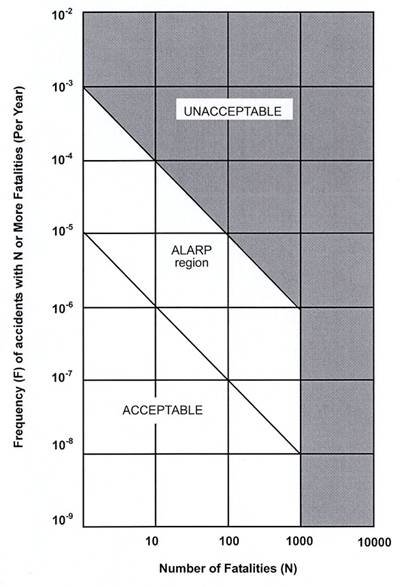

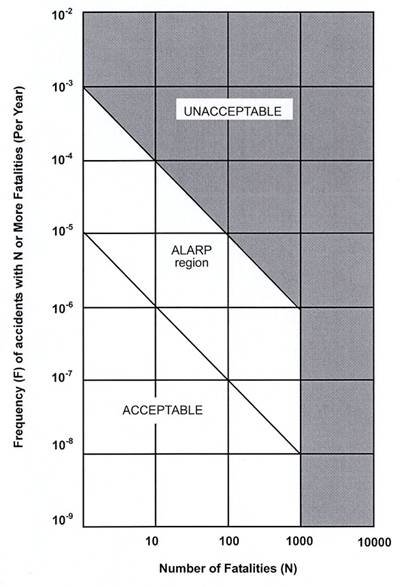

10.9

Societal risk expresses the risks to the whole population. The HKRG is

presented graphically in Figure

1. It is expressed in terms of lines plotting the

frequency (F) of N or more deaths in the population from incidents at the

installation. Two F-N risk lines are used in the HKRG that demark “acceptable”

or “unacceptable” societal risks. The intermediate region indicates the

acceptability of societal risk is borderline and should be reduced to a level which is “as low

as is reasonably practicable” (ALARP). It seeks to ensure that all practicable

and cost effective measures that can reduce risk will be considered.

Explosives Store (300kg

Capacity)

|

|

Figure 1 Hong Kong Government Risk Guidelines

10.10

The

objective of the QRA study is to assess the risk to life of the general public

from the hazards that arise

from the storage, use and transport of the explosives that are required to

facilitate the construction of the WIL project. The results of the QRA are

compared with the HKRG.

10.11

The detailed

requirements of the study are (see section 3.4.6 of

the EIA study brief):

·

To

identify all credible and applicable hazardous scenarios associated within the

boundaries of the construction site during the transport, storage and use of

explosives for blasting operations;

·

To

carry out a QRA to determine risks to the surrounding population in both

individual and societal terms;

·

To

compare the individual and societal risks with the Criteria for Evaluating

Hazard to Life stipulated in Annex 4 of the EIAO-TM;

·

To

identify and assess the practicable and cost effective risk reduction measures

as appropriate; and

The methodology of the hazard

assessment shall be agreed with the Director taking into account relevant previous

studies.

10.12

The elements of the QRA are shown schematically in Figure 2. It includes the following:-

·

Relevant data on the proposed storage magazine, the transport from the

magazine and the use of explosives at the blast face, as well as population and

vulnerable receptors, such as slopes, retaining walls etc., in the vicinity of

the tunnel construction and proposed transport routes were collected and

reviewed.

·

A structured study, involving a “what-if” analysis, was conducted to

identify all the hazards associated with the storage, transport and use of the

proposed blasting explosives. A review of literature and accident databases was

also undertaken. These formed the basis for identifying all the hazardous

scenarios for the QRA study.

·

The frequencies, or the likelihood, of the various outcomes that result

from the hazards associated with the storage and transport of blasting

explosives were taken from published references; such as the UK HSE, TNO, or

from previous EIA QRAs that have been accepted by the relevant authority. Where

necessary, these frequencies are modified to take account of project specific factors.

·

The frequencies of scenarios associated with the use of explosives at

the blast face were established using fault tree analysis, in conjunction with

a human factor assessment to evaluate human error probabilities.

·

For all identified hazards, the consequences of the event were modelled.

·

The consequence model employed by the QRA varied depending on the

location of any explosion, i.e. above or below ground, and upon the receiver,

i.e. slope, building or person.

·

The consequence and frequency data were subsequently combined using

ERM’s proprietary software Riskplot TM to produce the required risk estimates.

·

Finally, the results from the risk assessment were compared to the HKRG.

Recommendations have been made where required to ensure compliance with

relevant best practice, and to reduce the hazard by strengthening various

vulnerable receptors.

Figure 2 Schematic Diagram of QRA Process

Project Overview

10.13

WIL Construction is scheduled to commence in early 2009 for completion

in 2014. A significant length of the WIL will be excavated in rock. The amount

of rock to be extracted is approximately 480,000 m3. The rock excavation strategy as

well as the interfaces between the various contractors are shown in Figure 3.

10.14

Two types of explosives will be used for the construction of WIL by

Drill and Blast methods. These are:

·

Cartridged

Emulsion Explosives, which is classified as an explosive Class 1.1D under UN

Classification and as a Category 1 (Explosive and blasting agents) Dangerous

Goods under the Hong Kong Dangerous Goods Ordinance; and

·

Bulk

Emulsion Precursor, which is classified as an oxidising agent Class 5.1 under

the UN Classification system and as Category 7 (Strong supporter of combustion)

under the Hong Kong Dangerous Goods Ordinance. It is not classified as an

explosive until it is sensitised immediately prior to use.

10.15

Cartridged emulsion will be delivered from the Explosive Magazine to the

various construction sites by the appointed contractors using trucks licensed

by Mines Division. The bulk emulsion precursor will be transported to the blast

sites within the Adits/Tunnels by the appointed third party supplier. Bulk

emulsion will not be stored within the magazine.

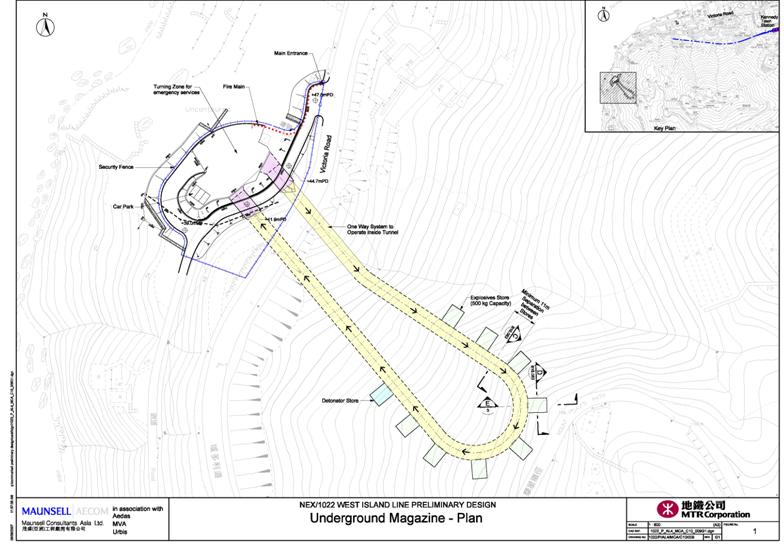

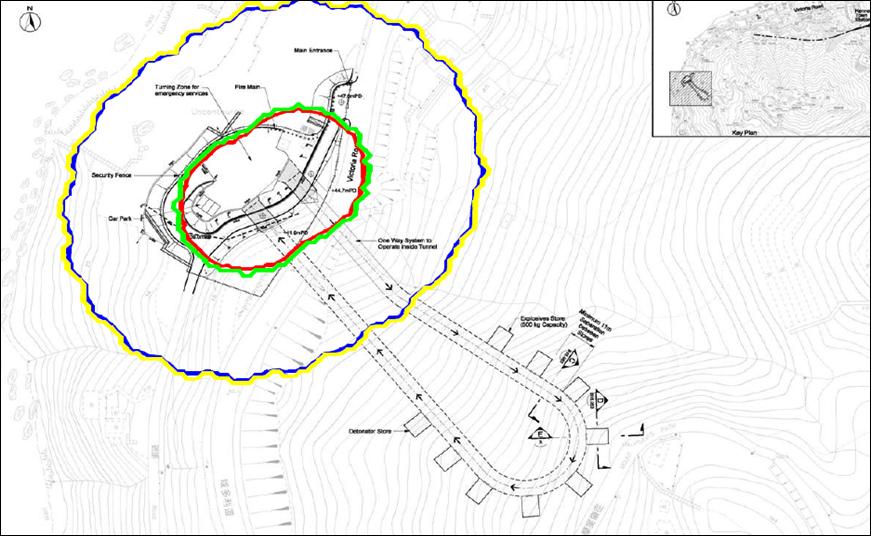

10.16

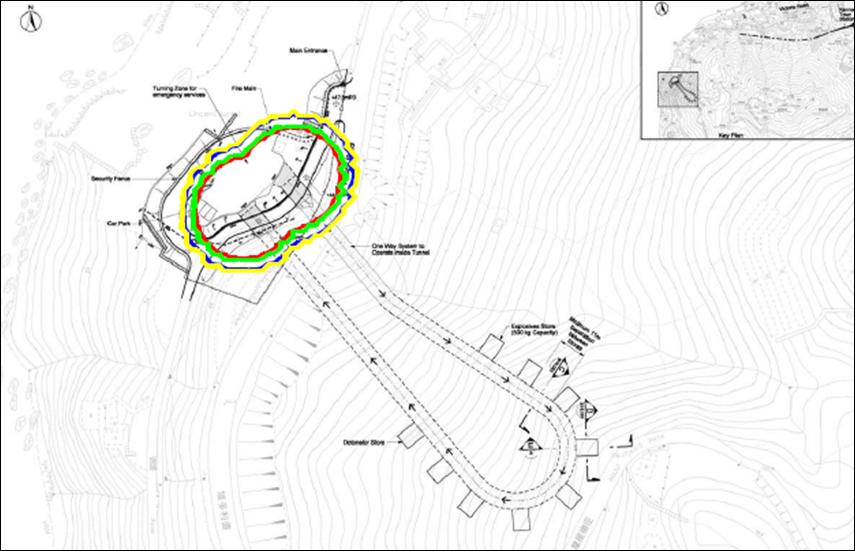

The location for the underground project magazine is an underground

store near a disused Government Facility Site with an entrance near Victoria Road (see Figure 4). The proposal is to use an existing flat platform of

land to access an underground store built into the mountainside beneath Mount Davis.

10.17

In much lesser explosive quantities, detonators, primers and detonating

cords will be used to initiate the blast at the working face depending on the

blast requirement. These are also classified as Class 1.1 explosives under the

UN classification system and Category 1 (Explosives and Blasting Agents) under

the Hong Kong Dangerous Goods Ordinance.

Detonators approved for use in Hong Kong

are of the Non-Electric Type, ie. chemically initiated.

10.18

For the purpose of this study, it is assumed that the construction

project will use cartridged emulsion explosives only. This represents the worst

case as the use of Bulk Emulsion Precursor will significantly reduce the amount

of cartridged emulsion (Cat 1.1D explosive) required to be stored and

transported.

Storage Magazine

Details

10.19

The proposed magazine is to be built into the mountainside beneath Mount Davis

and located near a disused Government Facility Site with an entrance near Victoria Road. The

design, construction and operation of the magazine, including the transport of

explosives and detonators to the point of usage, will be in accordance with the

Mines Division requirements.

10.20

The magazine will comprise an access tunnel 335m long, in an extended U layout, with explosive

storage chambers constructed off the side of the access tunnel. The access

tunnel portals will be located adjacent to one another and overlook the Sulphur

Channel. The explosive storage chambers will be located from the mid-point

along the tunnel, at the area with maximum depth below the ground surface.

10.21

The overall storage capacity of the magazine is 2400kg of blasting explosives.

The magazine is to comprise nine (9) chambers. Each chamber is designed to

store a maximum of 300 kg of

explosives. Eight chambers will store cartridged emulsion, detonating cords,

boosters, and primers. The ninth chamber will be used solely for the storage of

detonators.

10.22

The storage chamber for the detonators shall be sufficient to hold 9000

detonators, equivalent to two days supply. The detonators have a very low

explosive mass and contain less than 1 gramme of high explosives per detonator.

Therefore, the net explosive quantity from the total amount of detonators

stored is less than 9 kg.

10.23

The magazine design incorporates an automatic fire detection and alarm system

along the entire magazine tunnel length. Fire fighting measures such as fire

hydrant system are also provided in the magazine.

10.24

The magazine portals will have re-enforced concrete barriers or portal

barricades. These will be positioned in front of the entrance and exit adits of

the magazine, and designed in accordance with appropriate international

standards. The barricade walls are to be faced with a material designed to

retain any possible debris that may be propelled from the magazine adits.

10.25

The magazine will also have necessary security arrangements. These

include

·

2.5m high security fence topped with

razor wire;

·

Electric

flood lights evenly spaced along the security fence;

·

Close

Circuit Television (CCTV) camera mounted at 6m above the magazine ground level;

·

24hr

security patrols with at least two (2) armed guards during the day and three

(3) during the night;

·

Guard

dog; and

·

A

3 key system such that the authorised shotfirer, the contractor’s

representative, and the magazine manager have separate keys, with all three (3)

keys required for access to the chamber.

Transport Route Details

10.26

The overall intent is that Mines Division will deliver explosives daily

to a maximum of one construction site and the project magazine, from where

explosives will be transferred to the point of use by the contractors.

·

Two deliveries will be made each day to most of the delivery points. The

first delivery each day will be made in the early morning when roads will be

relatively quieter.

·

Loads will be limited to a maximum of 125kg per truck, which is the maximum load expected

for the project.

10.27

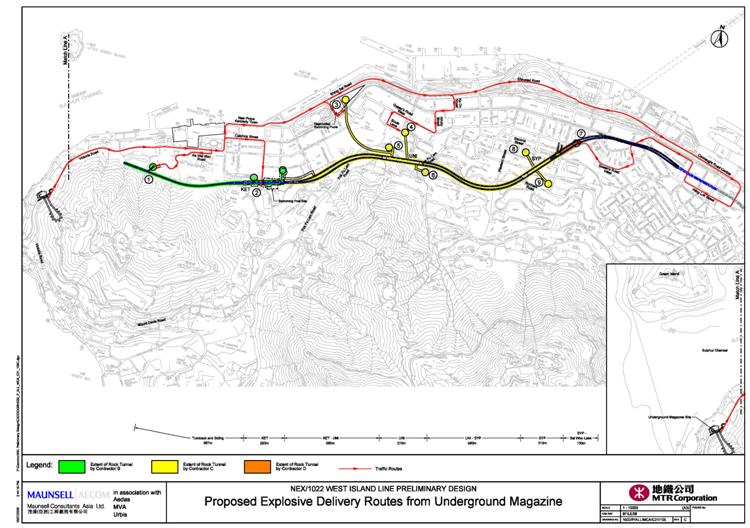

The Cartridged Emulsion Explosives will be delivered to the various

construction sites using the public roads as shown in Figure 5. The proposed site delivery points are the access shafts

at:

1.

Ex-police quarters, Kennedy

Town;

2.

Kennedy Town Swimming Pool (Smithfield Road);

3.

Site at Kennedy

Town Praya;

4.

Site at end of South Lane;

and

7.

Site at Sai Woo Lane.

10.28

According to the current programme of work, delivery of cartridged

emulsion explosives to points 1, 2, 3, 4 and 7 will be required from 2009 to

2011. Construction Phase I will require delivery of cartridged emulsion to

Points 1 to 4 and 7 while Construction Phase II will only require delivery of

cartridged emulsion to Points 3 and 4. There will be no overlap between the two

phases.

10.29

Other access points will not be used for delivery of explosives from the

magazine.

10.30

The maximum amount of anticipated daily deliveries of cartridged

emulsion by the contractors to points 1, 2, 3, 4 and 7 for Construction Phase I

is summarised in Table

1 below, while the maximum anticipated daily delivery to

points 3, 4 for Construction Phase II is summarised in Table 2 below.

10.31

The deliveries to point 7 will either be carried out in the morning or

in the afternoon. In addition to cartridged emulsion, detonating cords and cast

boosters, will be stored and transported. The explosives delivery quantities

are summarised in Table 1 and Table 2 for Construction Phase I and Phase II

respectively. Construction Phase I has the highest transport frequency per year

and hence been selected as the basis of the QRA.

|

Contractor

|

Delivery Point

|

Daily AM Delivery

(kg/day)

|

No of Trips AM

|

Daily PM Delivery

(kg/day)

|

No of Trips PM

|

Consumption (kg/day)

|

|

Contractor B

|

1 – Ex-police-quarters, Kennedy Town

|

80

|

1

|

0

|

0

|

80

|

|

2 – Kennedy

Town Swimming Pool

|

80

|

1

|

0

|

0

|

80

|

|

Contractor C

|

3 – Site at the Kennedy Town

Praya

|

125

|

2

|

125

|

2

|

500

|

|

4 – Site at the end of South Lane

|

80

|

1

|

80

|

1

|

160

|

|

Contractor D

|

7 – Site at the Sai Woo Lane

|

80*

|

1*

|

0*

|

0*

|

80

|

* Delivery may be carried out during PM instead of AM

Table 1 Explosives Delivery Quantities – WIL Construction Phase I

|

Contractor

|

Delivery Point

|

Daily AM Delivery

(kg/day)

|

No of Trips AM

|

Daily PM Delivery

(kg/day)

|

No of Trips PM

|

Consumption (kg/day)

|

|

Contractor C

|

3 – Site at the Kennedy Town

Praya

|

80

|

1

|

80

|

1

|

160

|

|

4 – Site at the

end of South Lane

|

80

|

1

|

80

|

1

|

160

|

Table 2 Explosives Delivery Quantities –

WIL Construction Phase II

10.32

The licensed explosives delivery vehicles will have the following safety

features:

·

Diesel powered

·

Battery and fuel isolation switches

·

Forward mounted exhaust with spark arrestor

·

Two fire extinguishers

·

Lockable wood lined steel magazine mounted on the vehicle tray

·

Fold down / up explosives warning signs and rotating flashing light

Use of Explosives Details

10.33

Explosives will be used for the initial construction of the storage

magazine as well as for the WIL alignment.

Adits / access tunnels will also be constructed by blasting.

10.34

The initial excavation of the magazine access tunnel will be by

mechanical methods. This will extend for 40 m until the tunnel has passed beneath Victoria Road.

Drill and blast excavation will then be adopted for a further 10 m for trial blasting, followed by full

face excavation if ground conditions are suitable.

10.35

The WIL alignment will be constructed in a similar

manner as the magazine adit/tunnel. The adit blasting will generally commence

at the bottom of the shafts, which are at typical depth of 20-40m but can be as deep as 80-90m near UNV Station. Blasting cover

protection will be provided to all shafts prior to blasting being carried out

in the adits.

10.36

The following safeguards will be implemented during

blasting.

10.37

Vibration Monitoring. It is a requirement to

monitor every blast in Hong Kong to record

blast induced ground vibrations. A dedicated Geotechnical Engineer is

responsible for ensuring that the controlling and other nominated sensitive

receivers for each blast are monitored to record the vibration levels in terms of Peak Particle

Velocity (mm/sec).

10.38

Trial Blasts. Trial blasts will be carried out for

the first series of blasts for the tunnels and adits and different areas or

sectors of the project if required. The trial blasts will be used to

demonstrate that the different types of blasting are safe, and the blasting

monitoring and control procedures are effective. The trial blasts are conducted

with cartridged emulsion explosives.

10.39

Advance Notice of Blasts. As part of the process of

issuing a License to Possess and a Permit to Use dangerous goods, Mines

Division will require that highly visible warning notices/signs be posted at

several locations to warn the public that blasting will take place. These

warning signs will be posted near the intended blasting location, even though

all blasts will be conducted underground. The Contractor is required to write

the blasting date and time on the notice.

10.40

Contractors are required by Law to have a comprehensive

Safety Management System and this is implemented and supervised by on-site

safety teams. Independent third party auditors make annual checks of

documentation and safety records.

10.41

Population

data used for the storage and transport risk assessment have been collected by

a combination of survey, the Code of Practice for Fire Safety (which defines

the maximum occupancy requirement for the design of commercial buildings),

Planning Department Zoning Plans and the census. Three types of population have

been considered:

·

Pedestrian population on footpaths and pavements next to delivery

routes;

·

Road population; and

·

Building population.

10.42

For the use of

explosive, all the features along the WIL alignment have been considered in a three

dimensional analysis. The features subject to the study include man made slopes

and retaining walls, existing man made features, natural terrain hillside and

boulders, existing buildings and structures, and utilities. The population data

was determined for the features that may be impacted by the hazards.

10.43

Details of

population adopted in this Hazard to Life assessment are provided in Appendix 10.

10.44

Hazard identification consisted of review of

explosive properties, review of scenarios in previous relevant studies, review of historical accidents and

discussions with blasting specialists. In addition, an expert panel review was

commissioned by ERM/MTRC to review the key assumptions and methodology for the

risk assessment for the storage, transport and use of explosives in the context

of the WIL Quantitative Risk Assessment. The review was held at ERM office in Hong Kong on 21-23 July 2008.

Type of Explosives

10.45

The blasting explosives configuration to be used for WIL will be either:-

·

A Detonator, containing less than a gram of high explosive such as PETN,

which is sufficient to detonate a Primer. The primer can be a single stick of

cartridged emulsion, or 12 grams of PETN or Pentolite (PETN/TNT

mixture). This in turn provides sufficient energy to set off the sensitised

bulk emulsion that is loaded into the blast hole.

·

Alternatively, a number of cartridged

emulsion sticks can be loaded into the blast hole and ignited by a single

detonator.

10.46

Both of the cartridged and bulk emulsions

contain mainly ammonium nitrate (single salt), water, hydrocarbon such as fuel

oil, and aluminium (only for the cartridged emulsion). Bulk emulsion is less

sensitive than the cartridged emulsion, as indicated by the requirement of an

explosive booster to initiate its detonation.

10.47

Cartridged Emulsion and Bulk Emulsion

Precursor will not explode due to friction and impact found in normal handling.

However, they can be detonated under heat and confinement or severe shock, such

as that provided by an explosive. In a fire, pools of molten ammonium nitrate

may be formed and if the molten mass becomes confined it may explode. In a fire

ammonium nitrate may melt and decompose with the release of toxic fumes (mainly

oxides of nitrogen).

Hazards of Explosives

10.48

Explosives present a hazard to both property and

people. This hazard manifests itself in the following five ways:

·

Blast and pressure wave;

·

flying fragments or missiles;

·

thermal radiation;

·

cratering; and

·

ground shock.

10.49

Blast and pressure waves can cause injury due

to sensitive human organs such as the ears and lungs. However, considerable

overpressures are required for fatalities to occur, and consequently people

need to be fairly close to the scene of the direct explosion effects to be

significant.

10.50

Other effects due blast or over-pressure are

associated with collapse of buildings and other structures/ objects or the

impact of debris and fragments from damaged building structure, and the vehicle

or container in which the explosives are held. Alternatively, injury may occur

when people are ‘swept’ away, or due to the violent movement of internal organs

within the body.

10.51

An explosion will involve the formation of a short

duration fireball, which is formed as the fuel content of the emulsion is

oxidised. However, although a fireball may be produced it will be of very short

duration. Generally it is considered that the thermal hazards from an

explosives detonation event are of less concern than the blast and fragment

hazards.

10.52

An explosion in an underground storage chamber may

produce external airblast from two sources; the exit of blast from existing

openings such as the magazine adits, and the rupture or breach of the chamber

cover by detonation. However, airblast hazards from a blast that ruptures the

earth cover are negligible relative to the ground shock and debris hazards.

10.53

The detonation of explosives liberates energy by a

rapid chemical reaction process, which produces and sustains a shock wave in

the surrounding rock. The degree of vibration of the rock particles decreases

with increasing distance from the blast. However, the vibration of the rock

particles can cause damage and structural failure to

buildings and other structures/ objects if it is sufficiently strong.

Review of Incidents

10.54

A review of reported safety incidents involving the

use of explosives (industrial applications) was carried out. Records were

retrieved mainly from the UK Health and Safety Executive (UK HSE)’s Explosives

Incidents Database Advisory Service (EIDAS), US Mine Safety and Health

Administration (MHSA) and Western Australia’s Department of Consumer and

Employment Protection (DOCEP). The records provided are also supplemented with

information obtained from various sources. Analysis of accident data are

provided in the Appendix 10.

Scenarios for QRA Study

10.55

Scenarios for the QRA study were identified based on the review of

incident records and previous similar QRA studies of explosives.

10.56

Scenarios considered for the transport of explosives are:

·

Accident involving explosives

delivered and transferred from magazine to delivery point 1

·

Accident involving explosives

delivered and transferred from magazine to delivery point 2

·

Accident involving explosives

delivered and transferred from magazine to delivery point 3 – Construction

Phase 1

·

Accident involving explosives

delivered and transferred from magazine to delivery point 3 – Construction

Phase 2

·

Accident involving explosives

delivered and transferred from magazine to delivery point 4

· Accident involving explosives delivered and transferred from magazine to

delivery point 7

10.57

Scenarios considered for the storage of

explosives are:

·

A fire leading to the detonation

of a full load of explosives within the magazine access tunnel whilst

transferring explosives to or from the appropriate storage chamber; and

·

A fire within any explosive

storage, or detonator, niche causing the detonation of the full quantity stored

within that particular niche.

10.58

Scenarios considered for the use of

explosives are:

·

Higher vibration generated by the

blast face due to human errors and other reasons such as manufacturing defects

causing deviation from the confirmed design;

·

Higher vibration and air

overpressure due to the detonation of a full load, 125kg, of explosives within the tunnel whilst

transferring explosives to the appropriate blast site.

10.59

The details of the frequency assessment are provided in

Appendix 10. The results are summarised below.

Frequency analysis for

Transport of Explosives

10.60

The basic event frequencies assumed for road accidents were based on that ‘The Risk

Assessment of the Transport of Explosives in Hong Kong QRA Report’ (ref. 4) due to its relevancy to WIL project, ie. transport

of explosives in Hong Kong.

|

Event

|

Event type

|

Value

|

|

Vehicle crash

|

Frequency

|

1.8 x 10-7 /km

|

|

Crash fire

|

Frequency

|

7.7 x 10-11 /km

|

|

Non-crash fire

|

Frequency

|

1.4 x 10-9 /km

|

|

Explosives initiation in fire

|

Probability

|

0.1

|

|

Explosives initiation in impact

|

Probability

|

0.001

|

|

Explosives initiation due to unsafe Explosives

|

Frequency

|

3.28 x 10-12 /km

|

Table 3 Explosives Initiation Fault Tree

Inputs

10.61

The frequency of explosives initiation during road transport is

thus estimated as 3.31 x 10-10/km, using a fault tree approach.

Frequency analysis for

Storage of Explosives

10.62

The overall initiating event frequency within the

storage magazine is based upon the UK HSE recommended value of 1 x 10-4

per storehouse year (see Section 6.1.1 of Appendix

10).

Frequency analysis for Use of Explosives

10.63

A failure mode analysis was carried out to

determine the potential failure modes associated with the use of explosives,

leading to higher vibration. The scenario of 2 or more maximum instant charges

(MIC) detonated at the same time was identified for the risk assessment. Fault

tree analysis was conducted, in conjunction with human factor assessment to

determine the occurrence frequency of 2 or more MIC detonated at the same time.

10.64

Table 4 summarises the overall frequency for

failure scenarios leading to higher vibration for the whole WIL project. The

blast linear length refers to the total pull length by the drill and blast

operation. For the WIL alignment, the blast linear length includes the two running

tunnels, two station blocks and associated adits and is estimated as about 9.3 km. For the Magazine Store, the blast

linear length covers the access tunnel and the 9 niches, and is estimated about

0.4 km.

|

Sections

|

Blast Linear

Length

|

Occurrence Frequency

for multiple MIC detonated at the same time per Section (Occurrence for the

whole project)

|

|

2MIC

|

3MIC

|

4MIC

|

5MIC

|

6MIC

|

|

WIL Alignment

|

9.3 km

|

4.09E-01

|

1.16E-03

|

6.86E-06

|

6.86E-06

|

6.86E-06

|

|

WIL Magazine Store

|

0.4 km

|

1.05E-02

|

2.73E-05

|

1.89E-07

|

1.89E-07

|

1.89E-07

|

|

Overall for WIL

project

|

9.7 km

|

4.19E-01

|

1.19E-03

|

7.05E-06

|

7.05E-06

|

7.05E-06

|

Table 4

Overall Frequency for Failure Scenarios leading to Higher Vibration for the

Whole Project Phase

10.65

This section gives a brief summary of the approach

adopted to model the consequences of an explosion within the magazine. Details

are given in Appendix 10.

10.66

The probability of fatality due to blast

over-pressure, have been estimated using the method detailed by the UK HSE Explosives

Storage and Transport Committee (ESTC) (ref. 5). The probability of fatality due to the possible damage

/ failure of a building, or slope, due to ground shock has also been modelled

using methods detailed with the Hong Kong CEDD Geo Reports (ref. 7-8). The fatality contours are calculated at 1%, 50% and 90% fatality.

10.67

Ground

shock or vibration levels at a given receptor will depend on the

distance between the receptor and the blasting point. The estimation of ground

vibration levels has used the method published in the Hong Kong CEDD Geo Guide

4 Cavern Engineering (ref. 6).

Consequence Distances

10.68

The

consequence distances for explosion events using the ESTC model are summarized

in Table 5. In this table, the ‘indoor’ refers to the

population located inside buildings, and the ‘outdoor’ refers to the population

located outside buildings ie in open area. A sample calculation of ground vibration level

is shown in Table 6.

|

Scenario

|

Description

|

TNT eqv. (kg)

|

Indoor

|

Outdoor

|

|

Harm Prob.

|

Impact distance

(m)

|

Harm Prob.

|

Impact

distance (m)

|

|

R01

|

Initiation of explosives during transport of

explosives from magazine to delivery point 01 via route 01

|

77

|

90%

|

13

|

90%

|

11

|

|

50%

|

15

|

50%

|

11

|

|

1%

|

36

|

1%

|

14

|

|

R02

|

Initiation of explosives during transport of explosives

from magazine to delivery point 02 via route 02

|

77

|

90%

|

13

|

90%

|

11

|

|

50%

|

15

|

50%

|

11

|

|

1%

|

36

|

1%

|

14

|

|

R03

|

Initiation of explosives during transport of

explosives from magazine to delivery point 03 via route 03

|

120

|

90%

|

15

|

90%

|

12

|

|

50%

|

18

|

50%

|

13

|

|

1%

|

42

|

1%

|

16

|

|

R04

|

Initiation of explosives during transport of

explosives from magazine to delivery point 04 via route 04

|

77

|

90%

|

13

|

90%

|

11

|

|

50%

|

15

|

50%

|

11

|

|

1%

|

36

|

1%

|

14

|

|

R07

|

Initiation of

explosives during transport of explosives from magazine to delivery point 07

via route 07

|

77

|

90%

|

13

|

90%

|

11

|

|

50%

|

15

|

50%

|

11

|

|

1%

|

36

|

1%

|

14

|

|

S01

|

Initiation of

explosives at delivery point 01

|

77

|

90%

|

13

|

90%

|

11

|

|

50%

|

15

|

50%

|

11

|

|

1%

|

36

|

1%

|

14

|

|

S02

|

Initiation of

explosives at delivery point 02

|

77

|

90%

|

13

|

90%

|

11

|

|

50%

|

15

|

50%

|

11

|

|

1%

|

36

|

1%

|

14

|

|

S03

|

Initiation of

explosives at delivery point 03

|

120

|

90%

|

15

|

90%

|

12

|

|

50%

|

18

|

50%

|

13

|

|

1%

|

42

|

1%

|

16

|

|

S04

|

Initiation of

explosives at delivery point 04

|

77

|

90%

|

13

|

90%

|

11

|

|

50%

|

15

|

50%

|

11

|

|

1%

|

36

|

1%

|

14

|

|

S07

|

Initiation of explosives at delivery point 07

|

77

|

90%

|

13

|

90%

|

11

|

|

50%

|

15

|

50%

|

11

|

|

1%

|

36

|

1%

|

14

|

|

M1

|

Explosion within magazine chamber 1 – 8

(Cartridge Explosives)

|

300

|

90%

|

17

|

90%

|

21

|

|

50%

|

17

|

50%

|

24

|

|

1%

|

22

|

1%

|

63

|

|

M2

|

Explosion within magazine chamber 9 (Detonators)

|

9

|

90%

|

5

|

90%

|

7

|

|

50%

|

5

|

50%

|

8

|

|

1%

|

7

|

1%

|

20

|

Table 5 Consequence Distances for Explosive Initiation using ESTC Model

|

Feature

|

Min

Distance from closest chainage (m)

|

Closest

Blast Chainage

|

Explosive

charge used (kg)

|

PPV

expected (mm/s) - 2 charges per delay

|

PPV

expected (mm/s) - 3 charges per delay

|

PPV

expected (mm/s) - 4 charges per delay

|

PPV

expected (mm/s) - 5 charges per delay

|

PPV

expected (mm/s) - 6 charges per delay

|

|

Bld1

|

33

|

SYPSHW_EB_100010

|

4.1

|

61

|

78

|

93

|

106

|

119

|

|

Bld2

|

29

|

SYPSHW_WB_100013

|

3.6

|

66

|

85

|

101

|

116

|

129

|

Table 6 Sample Calculation of PPV Level for each Feature at 2 or more MIC

detonated at the same time

Individual Risk Results

10.69

The individual risk (IR) contour associated with WIL

project are shown in Figure

6, Figure

7, Figure 8 and Figure 9. In these figures, the ‘indoor’ refers to the

population located inside buildings, and the ‘outdoor’ refers to the population

located outside buildings ie in open area.

10.70

The IR contours for ‘indoor’ and ‘outdoor’ have

been presented separately as the fatality probability is different for indoor

and outdoor population. The current version of the Riskplot model enables to

present indoor and outdoor fatality separately. This approach is more rigorous

than the equivalent fatality model since the effect distances for indoor and

outdoor fatality could be quite different.

For the

delivery routes, it is observed that no section of routes has an IR exceeding 5

x 10-8 per year. The highest risk contour at 1 x 10-7 (in

red colour of Figure 6 and Figure 7) represents the scenario of detonation of a full load

of explosives within the tunnel whilst transferring explosives to the blast

site, as part of use. For rock excavation using explosives, features at risk were

identified and the maximum risk of fatality to any individual is estimated as

4.4 x 10-10 per year. This is much lower than the Individual Risk

Criteria of 1 x 10-5 per year.

10.71

The IR contour for magazine is a 2 dimensional representation and hence

does not account for the relative elevation of the magazine portal with respect

to the receptor at risk. Also considering the most exposed individual in the

vicinity of the magazine, the individual risk is below 1 x 10-5 per

year and hence is acceptable.

Figure 6 IR of Delivery Route (Indoor)

Figure 7 IR of Delivery Route (Outdoor)

Figure 8 IR of Proposed Magazine (Indoor)

Figure 9 IR of Proposed Magazine (Outdoor)

Societal Risk Results

10.72

The societal risk results for the transport,

storage and use of explosives have been combined to produce the overall

societal risk results (Figure 10).

10.73

During phase 1 of the construction, there is an option to deliver

explosives to point 7 at AM or PM time, whereas deliveries to other points will

be as per the timing indicated (see Table

1). The FN curve for transport has been presented for

delivery to point 7 pm case which is the worst amongst the am and pm case for

pt 7 and it includes delivery to other points as well. The FN curve for use of

explosives covers construction of the WIL alignment and the magazine store.

10.74

The risks for all cases are within the Acceptable

Region as per EIAO.

10.75

The potential Loss of Life (PLL), or equivalent

fatalities per year, is given in Table 7. The total PLL for the whole WIL project is 3.44 x 10-5

per year, or equivalent to, one fatality every 30,000 years.

Figure 10 FN Curves

|

Case

|

PLL (per year)

|

Percentage Contribution (%)

|

|

Transport of

Explosives

|

|

|

Delivery of

explosives from magazine to delivery point 1

|

1.26E-06

|

3.66%

|

|

Delivery of

explosives from magazine to delivery point 2

|

1.68E-06

|

4.89%

|

|

Delivery of

explosives from magazine to delivery point 3

|

9.39E-06

|

27.29%

|

|

Delivery of

explosives from magazine to delivery point 4

|

6.04E-06

|

17.57%

|

|

Delivery of

explosives from magazine to delivery point 7

|

8.80E-06

|

25.57%

|

|

Use of

Explosives

|

|

|

Construction of

magazine

|

1.13E-08

|

0.03%

|

|

Construction of

WIL alignment

|

1.26E-06

|

3.67%

|

|

Detonation of

explosives within the tunnel whilst transferring explosives to the blast site

at delivery point 1

|

8.99E-08

|

0.26%

|

|

Detonation of

explosives within the tunnel whilst transferring explosives to the blast site

at delivery point 2

|

1.74E-07

|

0.51%

|

|

Detonation of

explosives within the tunnel whilst transferring explosives to the blast site

at delivery point 3

|

1.82E-06

|

5.29%

|

|

Detonation of

explosives within the tunnel whilst transferring explosives to the blast site

at delivery point 4

|

3.35E-06

|

9.73%

|

|

Detonation of

explosives within the tunnel whilst transferring explosives to the blast site

at delivery point 7

|

4.28E-07

|

1.25%

|

|

Storage of

Explosives

|

|

|

Proposed

magazine, including transport within the adits

|

9.04E-08

|

0.26%

|

|

Total

|

3.44E-05

|

100.00%

|

Table 7 Potential Loss of Life

References

1. MTR, West Island Line,

Consultancy Agreement C703, SYP and UNV Stations, and SHW to KET Tunnel, Blast

Assessment Report, Volume 1-8, June 2008

2. MTR, West Island Line,

Consultancy Agreement C704, KET Station and Overrun Tunnel, Modifications to

SHW Station, Blast Assessment Report, Volume 1-3, July 2008

3. MTR, West Island Line,

Consultancy Agreement C703, SYP and UNV Stations, and SHW to KET Tunnel,

Explosives Magazine at Victoria

Road Controlling Blast Report, June 2008

4. DNV The

Risk Assessment of the Transport of Explosives in Hong Kong, EPD

1997.

5. HSC,

Selection and Use of Explosion Effects and Consequence Models for Explosives,

Advisory Committee on Dangerous Substances, 2000

6. CEDD, Geoguide 4 - Guide to Cavern Engineering, Chapter 5,

pp77-78

7. CEDD, GEO Report 15, Assessment of Stability of

Slopes Subjected to Blasting Vibration, by H.N. Wong & P.L.R. Pang, 1992

8. CEDD, GEO Report 81 Slope Failures along BRIL Roads :

Quantitative Risk Assessment and Ranking, by ERM-Hong Kong, Ltd, 1999

9.

Lees, Frank P, Loss Prevention in the Process

Industries, second edition, 1996.

10.

Lees, Frank P, The Assessment of Major Hazards: A model for fatal injury

from burns, trans IChemE Vol 72, Part B, 1994.

11.

Merrifield, R. and Moreton, P A. An Examination of the Major Accident

Record for Explosives Manufacturing and Storage in the UK. Journal of Hazardous Materials

A:63 (1998) 107-118. 1998.

12.

Guidelines for Quantitative Risk Assessment. CPR18E. “Purple Book”.

Committee for Prevention of Disasters (The Netherlands). 1999.

13. Advisory

Committee on Dangerous Substances (ACDS), Major Hazard Aspects of the Transport

of Dangerous substances, HSC 1991.